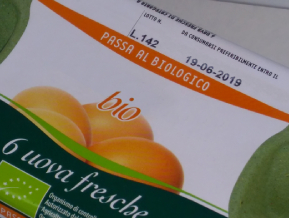

Cardboard packaging, as a simple tool for logistical and information needs, has assumed an increasingly important role as a vehicle for communication and branding, without foregoing the focus on aesthetics and image uniformity.

To meet the numerous requests for customisation and printing on cardboard boxes, trays and labels, Zanasi offers a complete line of low and high resolution printing systems.

The systems, designed to print text, barcodes, logos and images of different heights, use Drop on Demand piezoelectric printing technology, ensuring robustness and reliability for highly defined high-resolution printing, as well as perfectly traceable, readable and GS1 standard-compliant barcodes, on porous and non-porous surfaces.

The Thermal InkJet range of systems is capable of adhering perfectly to any surface of packaging and multipacks. They incorporate the control unit and ink cartridge, in a small space, allowing the latter to be replaced in a matter of seconds, offering high resolution printing up to 900 Dpi of alphanumeric characters and high quality data matrix.

TRACEABILITY AND COST REDUCTION

The wide working range of the heads allows you to take advantage of the entire printing surface available for endless customisation possibilities.

Direct printing of scannable information and barcodes on packaging gives you a real advantage that includes:

– the customisation of the message in real time

– the reduction of storage costs of pre-printed boxes

– the elimination of label costs and related management

– total traceability and identification of products on a logistics level

SCROLL DOWN

SCROLL DOWN