Products such as detergents, paints and varnishes, inks, lubricants and grease require specific packaging offering strength, certification and approval for the transportation of hazardous goods. The marking solutions must be flexible to adapt to the different types of packaging, but above all use special ink formulations to ensure good adhesion on various surfaces, where the printed message must resist friction and temperature fluctuations during storage and transport.

Zanasi inkjet systems have been designed to print clearly and visibly even in environments with variable environmental conditions that affect the printing results. Stability and reliability are a fundamental requirement not only for marking products with information relating to traceability, but above all for the implementation of the CLP regulation.

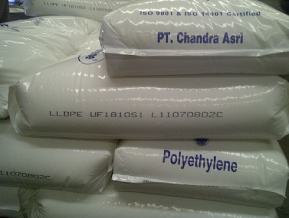

According to the provisions of the European CLP (Classification, Labelling and Packaging) regulation relating to the classification, labelling and packaging of substances and mixtures, products classified as dangerous with health risks or a danger to personal safety must bear a unique code called UFI, unique formula identifier.

The industry can count on design standards that include: the cabinet with high standards of protection, the automatic head cleaning process and the revolutionary mixing system to ensure consistent ink properties, which make the printer precise, stable and efficient.

SCROLL DOWN

SCROLL DOWN